High efficiency filters are a type of air filter that is designed to remove a large percentage of contaminants from the air that flows through it. These filters are commonly used in applications that require a high level of cleanliness, such as clean rooms, laboratories, and hospitals. The effectiveness of high efficiency filters is usually measured in terms of the filter's efficiency rating, which indicates the percentage of particles that are removed by the filter. This article will explore the different types of high efficiency filters, their benefits, and their applications.

There are several types of high efficiency filters, each with its own unique features and benefits. The most common types of high efficiency filters include:

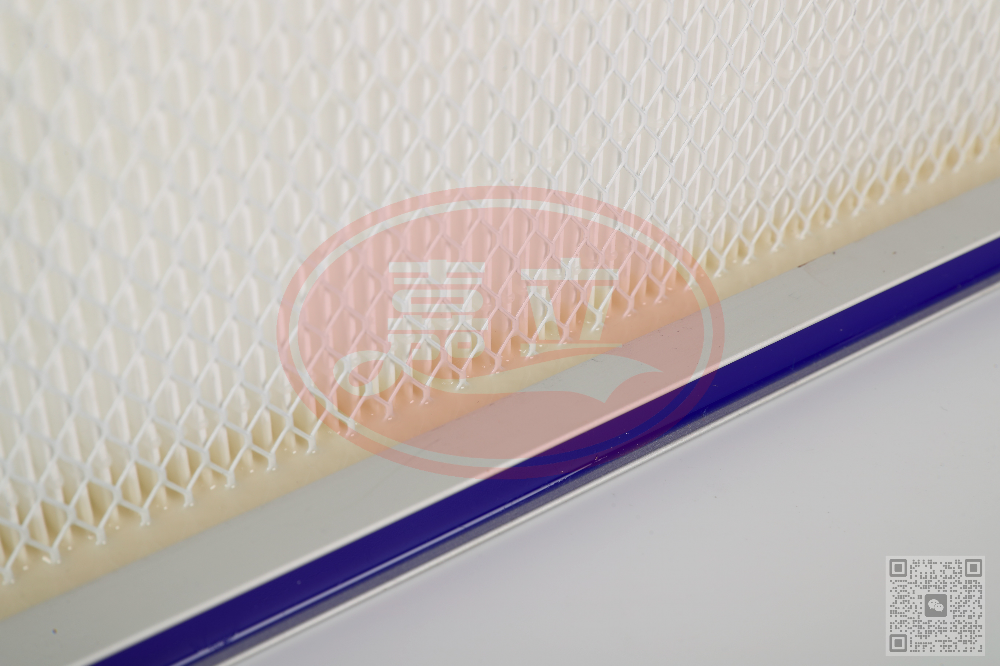

HEPA Filters: High Efficiency Particulate Air (HEPA) filters are the most common type of high efficiency filter. These filters are capable of removing particles as small as 0.3 microns with an efficiency rating of 99.97% or higher.

ULPA Filters: Ultra Low Particulate Air (ULPA) filters are similar to HEPA filters, but they are even more efficient. ULPA filters are capable of removing particles as small as 0.12 microns with an efficiency rating of 99.9995% or higher.

Activated Carbon Filters: Activated carbon filters are designed to remove odors, volatile organic compounds (VOCs), and other harmful gases from the air. These filters are commonly used in industrial applications and in homes with indoor air quality issues.

Electrostatic Filters: Electrostatic filters use static electricity to attract and trap particles in the air. These filters are often reusable and are commonly used in HVAC systems and air purifiers.

There are several benefits to using high efficiency filters, including:

Improved Indoor Air Quality: High efficiency filters can remove a wide range of contaminants from the air, including dust, pollen, mold spores, bacteria, and viruses. This can help improve indoor air quality and reduce the risk of respiratory illnesses.

Increased Energy Efficiency: High efficiency filters can help reduce the amount of energy that is required to cool or heat a space by reducing the load on HVAC systems. This can lead to lower energy bills and a smaller carbon footprint.

Reduced Maintenance Costs: High efficiency filters are designed to capture more contaminants than standard filters, which can reduce the amount of maintenance required on HVAC systems and other equipment.

Improved Equipment Performance: High efficiency filters can help extend the life of HVAC systems and other equipment by reducing the amount of contaminants that are introduced.

High efficiency filters are used in a wide range of applications, including:

Clean Rooms: High efficiency filters are essential in clean rooms, which are environments that are free from contaminants. Clean rooms are used in industries such as pharmaceuticals, electronics, and aerospace.

Hospitals: High efficiency filters are used in hospitals and other medical facilities to prevent the spread of airborne bacteria and viruses.

Museums and Archives: High efficiency filters are used in museums and archives to protect valuable artifacts from contaminants.

Industrial Applications: High efficiency filters are used in industrial applications to prevent the release of harmful particles and gases into the environment.

Residential Applications: High efficiency filters are commonly used in homes with indoor air quality issues, such as those with pets or allergies.

High efficiency filters are a critical part of many applications, from clean rooms to homes with indoor air quality issues. These filters are designed to remove a wide range of contaminants from the air, and their effectiveness is measured by their efficiency rating. Whether you are looking to improve indoor air quality, increase energy efficiency, or reduce maintenance costs, high efficiency filters are a great choice.

扫一扫咨询微信客服

扫一扫咨询微信客服